All-round surface heating for optimum temperature distribution

Extensive manufacturing know-how and outstanding material knowledge lie behind the unique Memmert heating system, continually improved over decades. The inner chambers, made of stainless steel, are deep drawn in fully automatic production facilities, and form the technical basis for the protected placement of heating elements on the four inner sides of the universal oven U, incubator I and steriliser S. In the CO2 incubator ICOmed and humidity chamber HCP, the doors and rear walls are heated as well.

The unbeatable advantages of the Memmert heating system at a glance

- The heating elements are protected, yet still lie close to the chamber load

- No corrosion or furring of heating elements

- Interior easy to clean, as it has no spaces or corners difficult to access

- The direct contact between the heating ribs and sliding shelves guarantees an excellent heat transfer, and thus an improved temperature distribution

- The arrangement of heating elements around the inner chamber ensures optimum temperature distribution (even when heavily loaded)

- The excellent thermal conductivity of the aluminium sheets attached to the outer side of the chamber additionally optimises temperature homogeneity and heat accumulation (e.g. in case of mains failure)

- Three components contribute to the optimum temperature distribution and temperature homogeneity in the chamber: Heat conduction through the material, thermal radiation from the surfaces, as well as natural convection or forced air circulation)

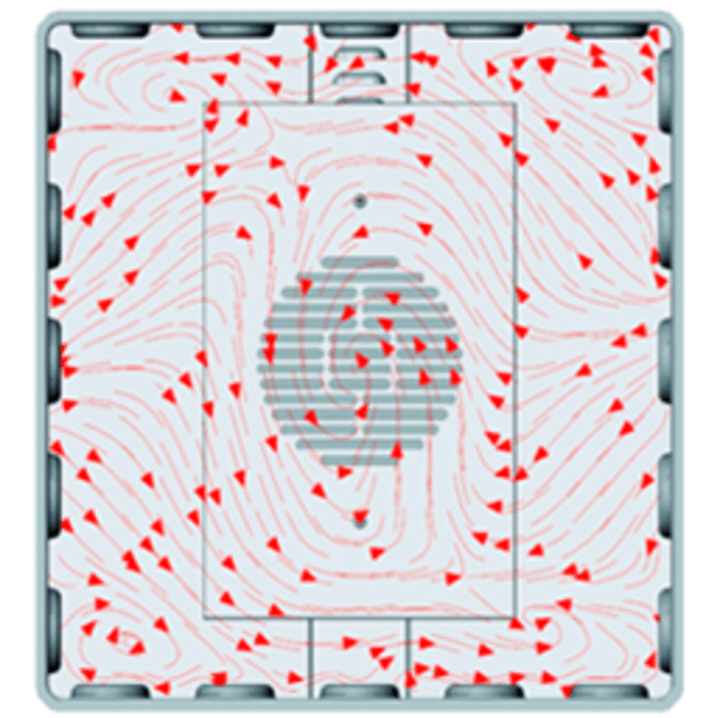

Air-flow with forced air circulation by fan

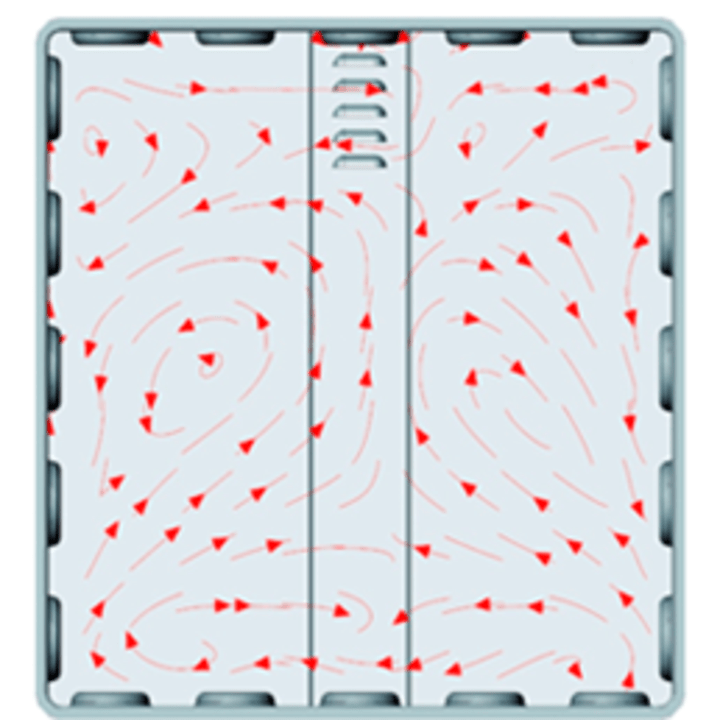

Air flow with natural convection

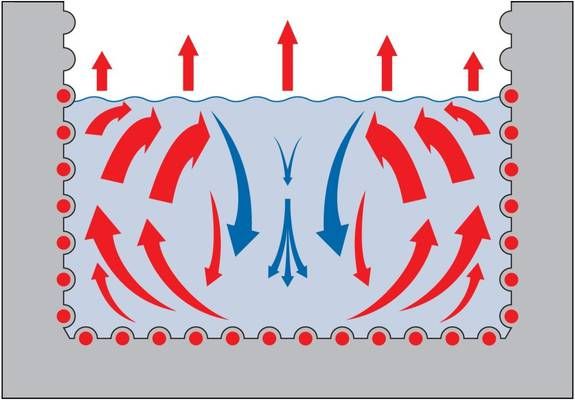

Also in water and oil baths

Optimum temperature homogeneity in the heating bath (waterbath and oilbath)

In the heating bath, the heating elements also lie in deep drawn ribs protected from wetness and furring.

Through this type of construction (heating elements in the floor and side walls), natural turbulence is created, providing optimal temperature distribution in the waterbath or oilbath.